FLEXIBLE AND ADAPTABLE

Flex-Flo™ Feed Delivery Systems

FLEXIBLE AND ADAPTABLE

Highlights

- Flex-Flo tubing is UV stabilized and provides excellent wear resistance.

- PVC tubing is extruded in-house under strict quality control to maintain exacting standards in the manufacturing process.

- Provides flexibility in facility design.

- Reduces dust, provides protection against insect and rodent contamination and reduces operation noise.

Built to Perform

Power Units

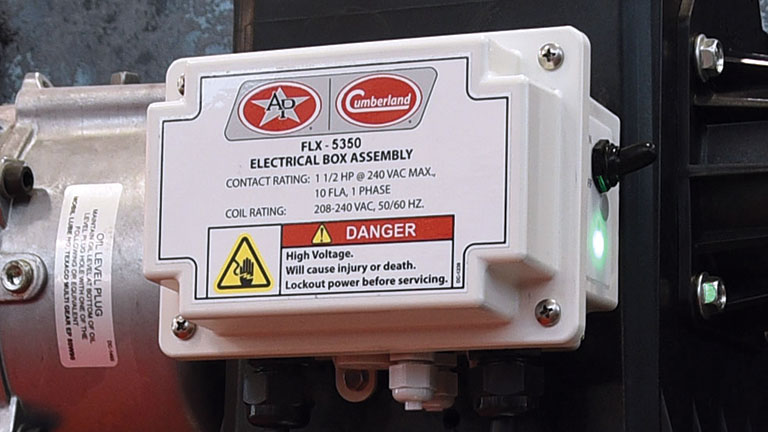

The Flex-Flo™ auger is driven by a 1/3 to 1-1/2 horsepower/standard 358 RPM totally-enclosed fan-cooled motor (other speeds are available for special applications). Whether direct or belt-driven, the drive system includes an easily-accessible maintenance port. A safety back-up switch automatically stops and restarts the motor if feed backs up in the line, indicated by a warning light. A thermal overload reset switch allows the system to be restarted once the motor has cooled.

SPECIFICATIONS

| Flex-Flo Model | Capacity | Tube Diameter | Application | |

|---|---|---|---|---|

| Model 220 | 15 lbs. (6.8 kgs.) per minute | 2.20″ / 55mm | ||

| Model 300 | 50 lbs. (22.7 kgs.) per minute | 2.95″ / 75mm | ||

| Model 350 | 100 lbs. (45.4 kgs.) per minute | 3.50″ / 90mm | ||

| Model 220EP | 18 lbs. (8.2 kgs.) per minute | 2.20″ / 55mm | Extended Pitch | |

| Model 300P | 50 lbs. (22.7 kgs.) per minute | 2.95″ / 75mm | Pellet Auger | |

| Model HR | 50 lbs. (22.7 kgs.) per minute | 3.50″ / 90mm | High Roughage | |

| Model 500 | 220 lbs. (99.8 kgs.) per minute | 5.00″ / 125mm |