Remote Management

Precise monitoring requires controls that are able to conform to the specific needs of your production facility. Cumberland control systems adapt to your climate and feeding requirements. They feature intuitive, user-friendly operation and construction built to withstand the rigors of the environment.

Resources

Learn more about Cumberland products and specifications in our brochure library.

About Us

Cumberland offers a full line of proven and dependable solutions to maximize the growth potential of every bird and your business. Products are engineered to be easy to install, simple to operate, durable and efficient.

Female Chain Feeder

Even, low-stress distribution of feed

Female Chain Feeder

Even, low-stress distribution of feed

Highlights

- Direct or belt drive options.

- Equal access of feed to all birds and assures uniform development.

- Simple controls.

Built to Perform

Durable Hoppers

Mini-hoppers are available in a full range of formats from 1-line, 1-way to 6-line, 2-way, and come standard with feed return wheels and feed level adjustments. Fill hoppers, mini-hoppers and our new single drive unit complete our full line of feeding equipment.

The traditional yoke weldment connecting the drive gears to the motor (an annoying source of shearing and misalignment in chain feeder systems) has been eliminated and replaced by a precision-machined design that reduces the number of parts, guarantees proper alignment and significantly enhances dependability.

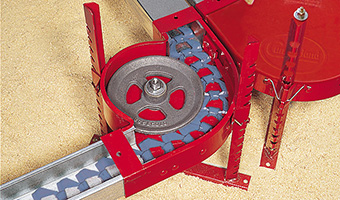

90-degree corner

Completely enclosed in a powder coated, steel housing, the corner mechanism is specifically designed for low maintenance and high performance. Mounted on a hardened steel base plate, the corner guide rail and fluted wheel provide maximum wear resistance while assuring smooth chain movement.

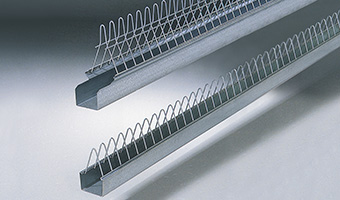

Troughs and Grills

Troughs are available in a smaller design for pullets and a larger trough (with a "feed saver" lip) for hens. Grills are available in almost any configuration to control access.

Trough couplers are available in a full range of formats: 6", 8" and 12" (15.2 cm, 20.3 cm and 30.5 cm) lengths with clip-on or wrap around hangers. Heavy duty "J" hangars are also available. Adjustable leg stands are available, as well as corners and couplers with metal leg stands.

Electronically Controlled System

The Cumberland Chain Feeder System is operated electronically. The standard speed system (60 feet or 18.28 meters per minute) uses either a 24-hour pin clock or a 24-hour digital clock, both of which can be preprogrammed to control all feeding and fill systems from the weigh bin, to the house, to the feeder itself. The high speed system (up to 120 feet or 36.58 meter per minute) can be purchased with an optional soft start controller to assist the motor in gradually increasing to full speed.