ASSUMPTION, Ill. (Date, 2021) — The new Flex-Flo XD ULTRA Unloader from Cumberland adapts to a variety of configurations and capacities to meet today’s demanding production requirements.

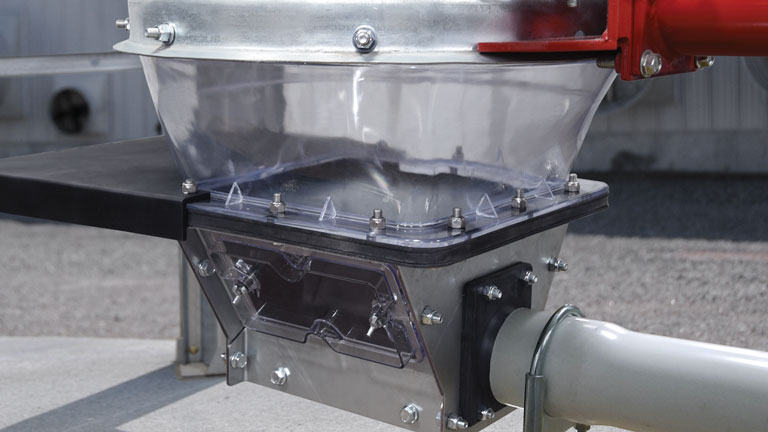

The Flex-Flo XD ULTRA Unloader features a wear plate made from fiberglass-filled nylon material that provides four times the wear resistance compared to galvanized wear plates. The wear plate can be replaced in a fraction of time with a standard wrench. In addition, the boot features a new geometry that offers a 50% larger opening, helping to minimize feed bridging events.

Made from heavy-duty galvanized or stainless steel, the unloader housing increases durability and limits corrosion.

“The Flex-Flo XD ULTRA is more than an unloader. It’s a new way to think about the efficient and cost-effective delivery of feed,” said Brian Rieck, senior manager of product management for AGCO, Cumberland’s parent company.

Other features include the following:

- The new geometry of the system offers a low-profile design, providing increased ground clearance under the unloader for cleaning and service activities.

- The tube anchors are made from the same durable fiberglass-filled nylon as the wear plate and are injected for a more accurate fit and alignment, helping to reduce wear.

- Single, twin and quad versions all feature common wear plates, tube anchors and bearings. Anchor bearings are fastened directly to the unloader body, eliminating the need for muffler clamps and potential wear issues.

- The clear boot and custom-molded access window provide for easier feed-flow visual inspections.

- Custom-cut EPDM gaskets seal the tube anchors and transfer plates, providing a water-tight seal that prevents the intrusion of moisture into the feed.

A retrofit kit is also available for existing Flex-Flo unloaders that are worn out, but the boot and slide gate are in good condition. For additional information, producers can contact their Cumberland dealer or visit www.cumberlandpoultry.com.

About Cumberland

Cumberland® is a brand within AGCO Grain & Protein, a key business unit of AGCO (NYSE:AGCO). AGCO Grain & Protein is represented by five umbrella brands – Cimbria®, GSI®, Automated Production® (AP), Cumberland® and Tecno®. Each brand provides complete solutions in the markets they serve. For more information, visit www.automatedproduction.com. For company news, information and events, please follow us on Twitter: @CumberlandPoul1.

About AGCO

AGCO (NYSE:AGCO) is a global leader in the design, manufacture and distribution of agricultural machinery and precision ag technology. AGCO delivers customer value through its differentiated brand portfolio including core brands like Challenger®, Fendt®, GSI®, Massey Ferguson® and Valtra®. Powered by Fuse® smart farming solutions, AGCO’s full line of equipment and services help farmers sustainably feed our world. Founded in 1990 and headquartered in Duluth, Georgia, USA, AGCO had net sales of $9.1 billion in 2020. For more information, visit www.AGCOcorp.com. For company news, information and events, please follow us on Twitter: @AGCOCorp. For financial news on Twitter, please follow the hashtag #AGCOIR.